- Home

- Filling Machine

- Automatic Liquid Filling Machine System

Automatic Liquid Filling Machine System Solution

With the rapid development of my country's packaging industry and the continuous expansion of consumer demand for cosmetic preparations, dairy products, beverages, and other products. Liquid filling machines are favored by more and more manufacturers because of their easy operation and high production efficiency. However, in the actual use process, the waste of raw materials and cross-contamination caused by card machines, splashing, and canning accuracy errors also cause headaches for manufacturers.

With the rapid development of my country's packaging industry and the continuous expansion of consumer demand for cosmetic preparations, dairy products, beverages, and other products. Liquid filling machines are favored by more and more manufacturers because of their easy operation and high production efficiency.

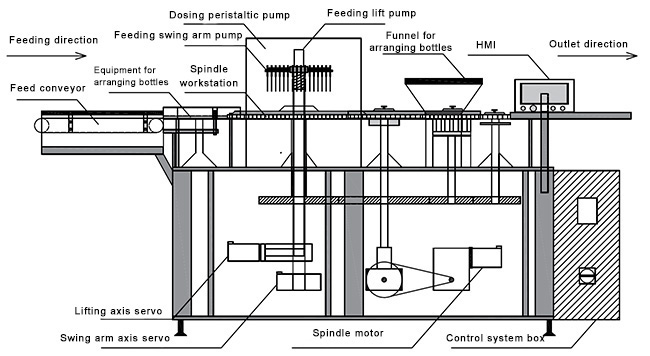

System structure

Lifting Servo

Driven by the HD330 servo system, it can complete the feeding liquid entering and exiting synchronously in the swing arm canning section.

Independent research and development, stable and efficient

The core products of the entire system solution are high-performance equipment independently developed. Ensure that the entire electronic control system can achieve higher stability and compatibility. At the same time, it provides customers with more flexible solutions and more efficient after-sales service.

Replacing the tedious with simple, accurate, and reliable

The system feeds the swing arm shaft and feeds the lift shaft following the feedback pulse of the spindle encoder to make the electronic cam track motion. Compared with mechanical cams and positioning methods, its movement method is simpler, more precise, and more stable.

Missing detection function reduces losses

The no-bottle-no-can detection process can effectively realize the detection of missing bottles in the empty station interval. Control the opening and closing of the liquid delivery valve in the working area of the corresponding liquid pump. Greatly reduces the waste and loss of material canning.

Simple operation and comprehensive functions

We has been deeply involved in the field of industrial control automation for many years. Always adhere to scientific and technological innovation as the core development strategy. Unswervingly provide safe, reliable, and efficient products and solutions for the industrial control industry.

LEAVE A MESSAGE

LEAVE A MESSAGE